Product List

Anti-corrosion steel pipe

Product type: 3PE anti-corrosion steel pipe, coating steel pipe, epoxy coated steel tube, FBE coated steel pipe, Thermal insulation coating steel pipe, Cement mortar lining anti-corrosion steel pipe

Product Standard: DIN 30670, DIN 30673; ISO21809-1,AWWA C205,AWWA C213,AWWA C215,AWWA C203,CSA Z245.20-02 etc.

Coated pipe OD: 1/2”-100” (21.3 -2540mm)

Steel Pipe Corrosion prevention always is a problem for big project construction. The steel pipe anti-corrosion using transport pipeline cited by the use of the environment and transport medium shadow pipeline corrosion chemical or electrochemical reaction. Or by the metabolic activities of microorganisms to slow down or prevent corrosion and deterioration of the pipe.

For the steel pipe anti-corrosive material to choose, that will be more important. Good anti-corrosive material will protect the steel pipe with a long lifetime. Here is the anti-corrosive material that usually chooses in the anti-corrosive. Anti-corrosive pipeline materials mainly include 2/3P anti-corrosion (polyethylene), 2/3PE anti-corrosion (polypropylene), single layer epoxy powder anti-corrosion, epoxy coal tar anti-corrosion, etc.

The steel pipe the outer wall anti-corrosion form like these.

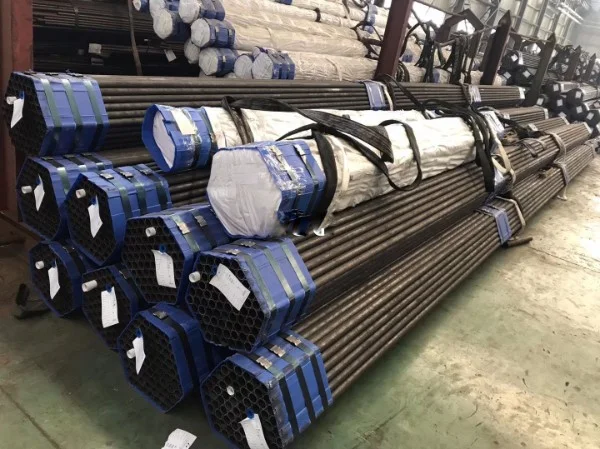

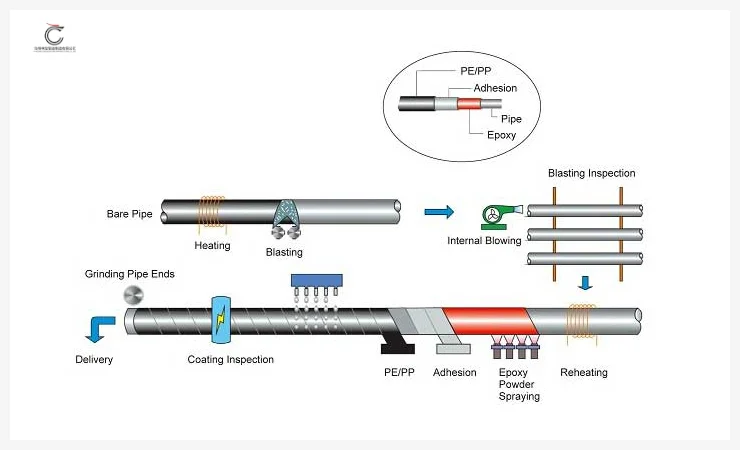

3PE anti-corrosion generally consists of 3 layers:

One layer of epoxy powder (FBE>100um)

Two-layer adhesive (AD) 170~250um

Three-layer polyethylene (PE) 1.8~3.7mm

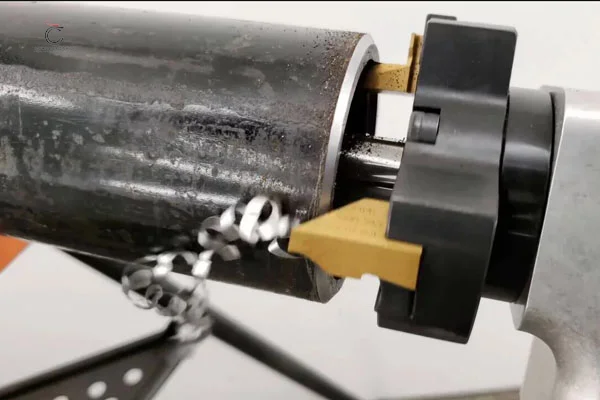

Anti-corrosion construction

Coating construction has a great influence on the performance of the coating. There are some failures to achieve the expected anti-corrosion effect due to improper construction methods. The only way to make the coating achieve high quality. It must be strictly by their construction condition can they form a normal coating and achieve the expected anti-corrosion protection effect.

1. The substrate must undergo strict surface treatment.

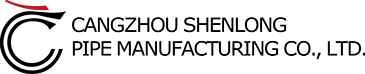

2. To ensure the necessary coating thickness

3. Control environmental factors such as temperature and humidity at the painting site

4.Control the coating interval time

There are various anti-corrosion ways to protect the steel pipe. Here it is.

1. Greasepaint - the atmospheric corrosion undemanding environment.

Grease coating is a dry oil for a class of the main film coatings. Which is characterized by ease of production, good brush ability, good weather ability on the object surface, inexpensive, flexible film. Drying oils are often in conjunction with the anti-rust pigment composition of the anti-rust paint used in the corrosion-insensitive atmospheric environment.

2. Phenol resin coating

Alcohol-soluble phenol resin, a modified phenolic resin, phenolic resin, or the like. Alcohol-soluble phenolic resin coating corrosion resistance is better, the inconvenience, but the construction is not very good flexibility, adhesion, has limited application. Therefore often requires the modified phenolic resin. Such as rosin-modified phenolic resin and tung oil refining, adding various pigments can be obtained by grinding a variety of enamel, tough film, inexpensive, and widely used for furniture, doors and windows, painting. Pure phenolic resin coating adhesion, water resistance to heat, corrosion resistance, good weather ability.

3. Epoxy coatings

Good adhesion of epoxy coatings have excellent adhesion to metal, concrete, wood, glass, etc.; alkali, oil, and water, excellent electrical insulation properties. However, the aging resistance. Epoxy anti-corrosion coating is usually composed of two components of an epoxy resin and a curing agent. The nature of the curing agent also affects the performance of the film. The commonly used curing agents are ① fatty amines and their modified compounds. Features can be cured at normal temperature, the greater toxicity of unmodified aliphatic amines. ② aromatic amines and their modified product. The characteristics of the reaction are slow, and often have to heat curing virulent. (3) a polyamide resin. Characterized by good weather resistance, less toxic, good elasticity, corrosion resistance can be somewhat less. ④ phenolic resins, urea resins, and other synthetic resins. These resins and epoxy resins and crosslinked film after baking at high temperature, the film has outstanding corrosion resistance and has good mechanical properties and decorative. Epoxy ester resin paint is an epoxy ester resin as a film-forming substance a single component coating systems. The epoxy ester resin from an epoxy resin, and vegetable oil fatty acid esterified collectively made. The paint and general epoxy coatings compared to lower-cost, poor alkali resistance. Commonly used for a variety of metal primer and chemical plants outdoor equipment anti-corrosion paint.

4. Polyurethane coatings

A polyurethane resin for anti-corrosion coatings often contains two components: an isocyanate group-NCO and hydroxy. When using two-component mixing reaction curing generates polyurethane (PU).

Features: ① physical and mechanical properties of polyurethane coatings. Film hard, flexible, bright, plump, wear-resistant, strong adhesion. ② corrosion resistance is excellent. Oil, acids, chemicals, and industrial emissions. The alkali resistance is slightly lower than the epoxy coatings. ③ aging resistance than epoxy paint. Commonly used as a top coat, but also can be used as a primer. The ④ polyurethane resin and a variety of resin miscible, the recipe can be adjusted within a wide range of use to meet a variety of requirements. ⑤ can be cured at room temperature or heat curing, can be cured at low temperatures (0 ℃). ⑥ polyisocyanate component poor storage stability must be isolated from moisture to avoid jelly. The high price of polyurethane coatings, but long life.

5. Polyethylene, polypropylene resin coating

Anti-corrosion coatings of polyethylene resin are a monomer made of resin for the coating of the film-forming substance. The polyethylene coating mass production. Strong sealing polyethylene pipe anti-corrosion, high mechanical strength, waterproof and strong, stable quality, convenient construction, applicability, and does not pollute the environment. PE

6. Heavy anti-corrosion coatings

Heavy anti-corrosion coating is relatively general anti-corrosion coatings. It is under severe corrosion conditions than the general corrosion coatings, anti-corrosion effect several times more than the anti-corrosion coatings. Which is characterized by resistance strong corrosive media outstanding performance, durability, and service life of more than a few years. Mainly used for marine structures and chemical equipment, storage tanks, and pipelines.