Product List

Spiral Welded Steel Pipe

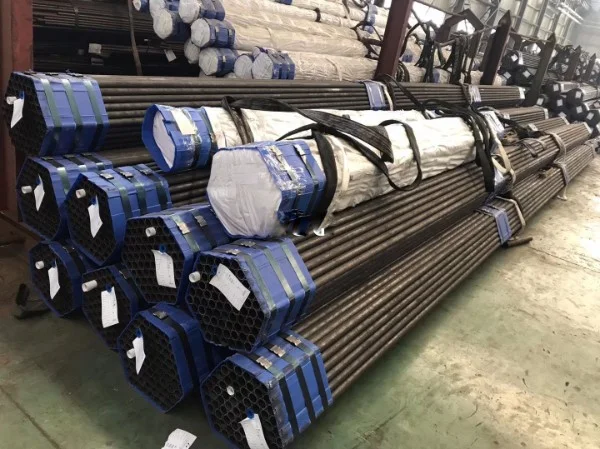

Product name: Spiral welded steel pipe,Spiral Steel Pipe, SAWH steel pipe, SAWH pipe, ssaw pipe, spiral steel pipe, spiral submerged arc pipe, spiral welded pipe, SSAW Steel Pipe, HSAW steel pipe, helical welded pipe, SSAW Hollow pipe

Materials: GR.B, X42, X52, X60, ST35, ST52, S235JR, S355JR, SS400, SGP, STP G370 etc.

Standard: API 5L, ASTM A53, A139, A515, A252, A672 etc.

Spiral welded steel pipe type:

SAWH steel pipe, SSAW steel pipe, HFW Steel line pipe, HFW steel pipe, Galvanized Spiral welded steel pipe, 3PE coated spiral welded steel pipe

1.Spiral welded steel pipe materials: GR.B, X42, X52, ST37, ST52, S235JR, S355JR, SS400, SGP, STP G370 etc.

2. Spiral welded steel pipe standard: API 5L, ASTM A53, A139, A515, A252, A672 etc.

3. Spial welded steel pipe specification:

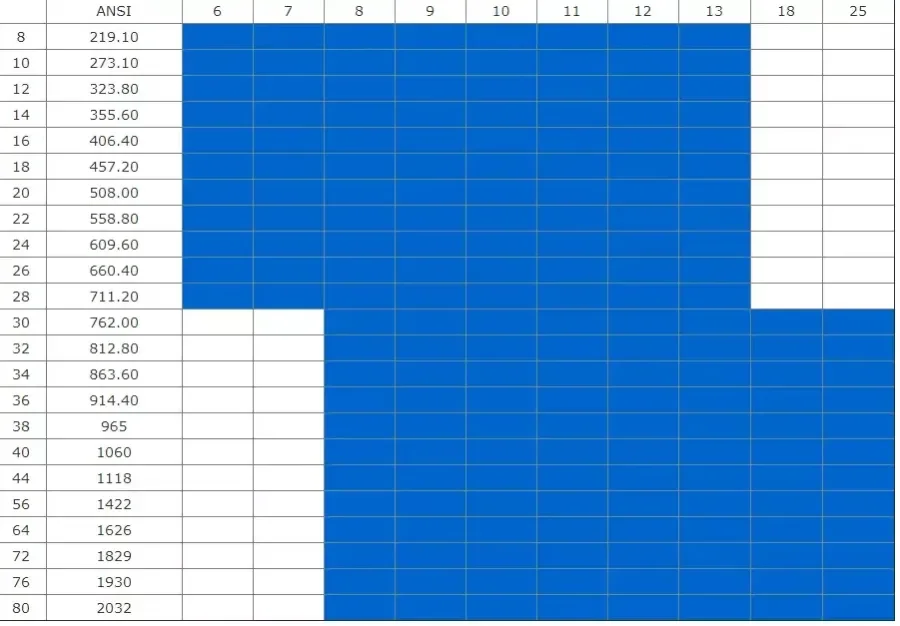

OD: 219.1mm-3000mm.

WT: 4mm – 25.4mm.

Length: 6m - 18m.

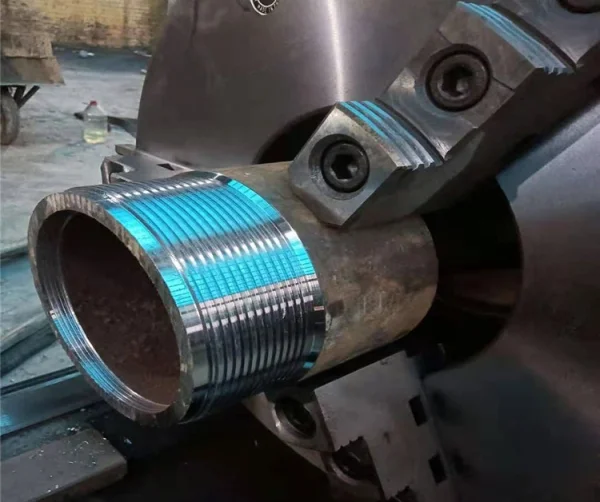

4. End: plastic cap in the both end, pipe clamp.

5. Surface:oiled, black painted or varnish, galvanized, 3PE, FBE, or other epoxy coating.

6.Spiral welded steel pipe inspection:hydrostatic testing, ultrasonic testing, X-ray inspection.

7. Spiral welded steel pipe application: bridges, construction, water, oil and chemical industry.

Standard of Spiral welded steel pipe

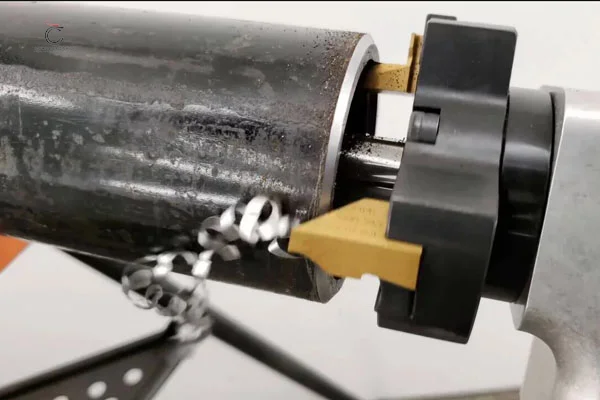

SSAW steel pipe is made up of hot-rolled coiled steel using a double-sided submerged arc welding method. The welding process allows steel pipe manufacturers to produce large-diameter steel pipes suitable for different applications.

| Standard | Specification |

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

| API 5L | Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

| A252 | Standard Specification for Welded and Seamless Steel Pipe Piles |

| A500 | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions |

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties |

Spiral Welded Steel Pipe advantages

Shenlong spiral welded pipe has uniform wall thickness and 100% nondestructive testing of the weld seam. We have a short delivery time, more than 30,000 tons of steel pipes in stock all year round, and a complete range of steel pipe specifications; we have 6 testing procedures to ensure that the quality of the products leaving the factory are all qualified; we also have 10 production lines for fast delivery.

Spiral Welded Steel Pipe Quality Inspection:

Specific detection is as below:

visual inspection. Trough the surface inspection found that there are many weld surface defects and deviations on sizes.

physical test. Further testing on the spiral steel pipe by ultrasonic, radiographic, and magnetic permeability and so on.

strength test. Through pressure test to check whether weld seam under pressure is tight enough to ensure the strength of spiral steel pipe.

density test. By kerosene test, load test and flush water test and other test to check whether there is no-dense spiral pipe defect when storing liquid or gas, such as penetrating cracks, pores, slag, incomplete penetration and loose organization.

hydrostatic testing. By hydrostatic test to check for each pipe to ensure leakage does not occur in the larger internal pressure situation.

Is through these five strict and tight quality technical detection technology, it ensures the spiral steel pipe factory in the long-term performance and stability

Spiral Welded Steel Pipe feature

SSAW steel pipe is the raw material of strip coil, often temperature extrusion molding, automatic double-wire double submerged arc welding process made of spiral seam pipe. Spiral steel pipe will strip into the pipe unit, the multi-roll rolling, strip rolled up, forming a circular gap opening gap, adjust the squeeze roll reduction, the weld gap control in the 1 ~ 3mm, and make both ends of the weld flush.

Spiral Welded Steel Pipe Technical Data

What is spiral welded steel pipe?

Spiral welded steel pipe refers to a steel pipe with seams on the surface that is welded by bending and deforming a steel strip or steel plate into a round, square or other shape. According to different welding methods, it can be divided into arc welded pipe, high frequency or low frequency resistance welded pipe, gas welded pipe, furnace welded pipe, Bondi pipe, etc. According to the shape of the weld, it can be divided into straight seam welded pipe and spiral welded pipe. Electric welded steel pipes are used in oil drilling and machinery manufacturing. Furnace welded pipes can be used as water and gas pipes, etc., large-diameter straight seam welded pipes are used for high-pressure oil and gas transportation, etc.; spiral welded pipes are used for oil and gas transportation, pipe piles, bridge piers, etc. Welded steel pipes have lower cost and higher production efficiency than seamless steel pipes.

The production process of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is fast. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe. However, compared with the same length of straight seam pipe, the length of the weld is increased by 30~100%, and the production speed is lower. Therefore, most of the welded pipes with smaller diameters use straight seam welding, and most of the welded pipes with large diameters use spiral welding.