Product List

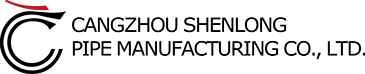

Slip on flange

Product name: Slip on flange, SO flange, slip on flange weld, Slip on flanges, reducing slip on flange, reducing flanges

Standard: ASME B16.5, AWWA C207, EN1092-1, BS4504, GOST12820, DIN etc.

Specification: 1/2 "to 24"

Pressure: 150LB, 300LB, 600LB, 900LB, 1500LB, PN10, PN16, PN25,PN40 etc.

Slip-on flange feature material:

Carbon steel flange (CS) : ASTM A105, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel flange (SS) : ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy flange (AS) : ASTM A182F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, ST45.8;

Application range of slip-on flange:

Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, so to some extent, it is most popular for our customers. However, customers should bear in mind that this initial cost saving may be diminished by the additional cost of the two fillet welds required for proper installation. Moreover, weld-neck flanges have a higher lifespan than slip-on flanges under duress.

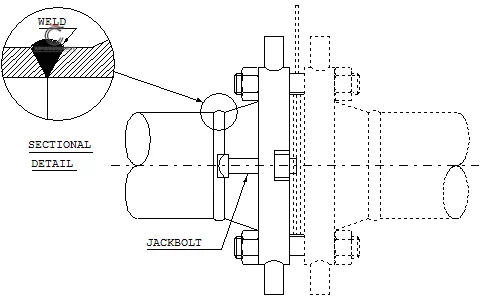

The slip-on flange is positioned so the inserted end of the pipe or fitting is set short of the flange face by the thickness of the pipe wall plus 1/8 of an inch, which thus allows for a fillet weld inside the SO flange equal without doing any damage to the flange face. The back or outside of the slip-on flange or SO flange is also welded with a fillet weld.

Advantages ofslip on flange:

Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for our customers.

1. Low cost installation

2. Less time needed to spent on ensuring the accuracy of the cut pipe

3. They are somewhat easier to align

4. The slip-on flanges have low hub because the pipe slips into the flange before welding

5. The flange is welded both inside and outside to provide sufficient strength

6. They prevent leakage

Slip on flange feature:

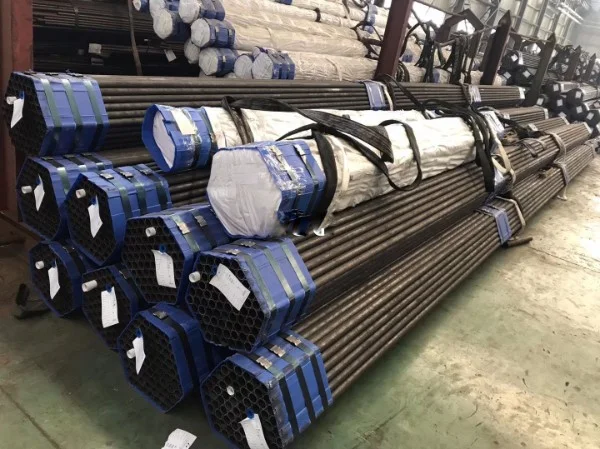

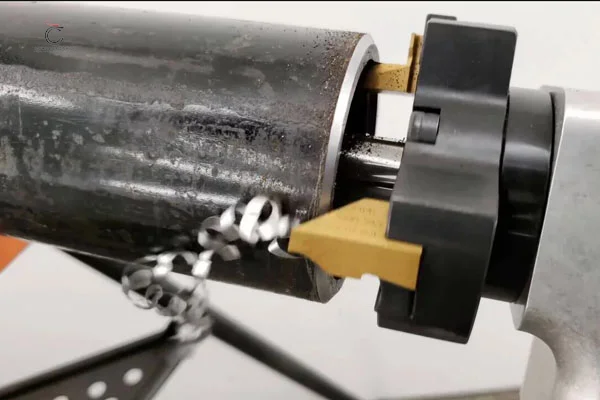

Connection type: single side welding, double - sided nut connection. Product features:Good appearance, smooth surface, acid and alkali resistance, corrosion resistance, strong texture performance. Production process: oxygen furnace opening, overall forging or finished forging cutting molding. Processing mode: high precision CNC lathe turning, CNC rocker drilling.

Product quality control of Slip on flange:

1. To ensure the product performance, the raw materials from well-known manufacturers such as Bao Steel and Baotou Iron and Steel are selected . The raw materials are inspected once entering the factory, and the samples are produced before mass production.

2. Using the forging process, the round steel after forging will improve the mechanical properties of the metal, improve the internal organization of the metal.Therefore,the bearing capacity is stronger, and stability will be better.

3. CNC lathe processing, accurate size, with enough material.product surface will be bright without scratches.

4. Company name, specifications, furnace number and other information will be marked on each product, and every process of the product can be traced back.

Slip-on flange markings:

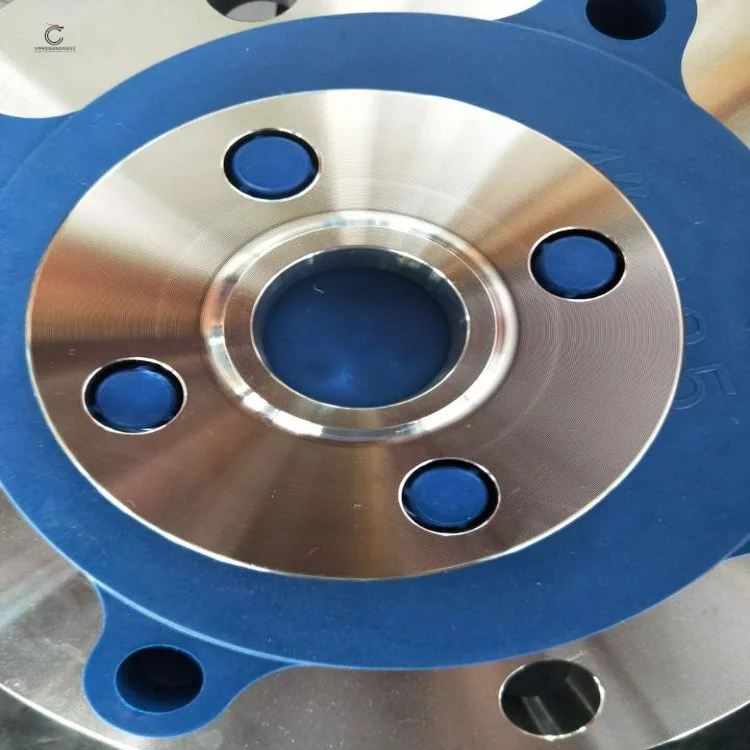

1.Plastic film will be used on each layer to protect the surface.

2. For all stainless steel are packed by plywood case. For bigger size carbon flange are packed by plywood pallet. Or can be customized packing.

3. Shipping mark canbe madeon request.

4. Markings on products can be carved or printed. OEM is accepted.