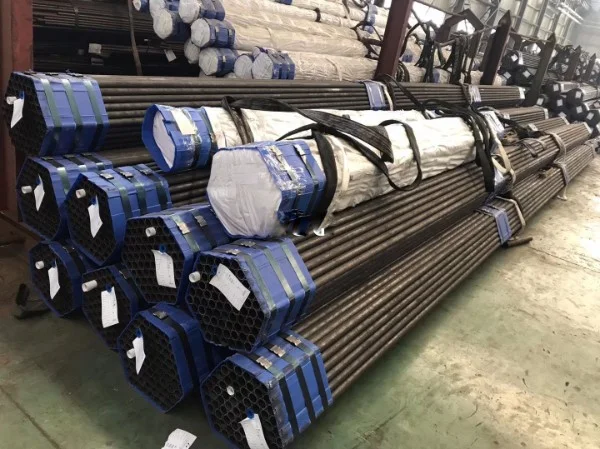

Product List

LSAW Welded Steel Pipe

Product name: LSAW Welded pipe, SAWL steel pipe, Straight seam steel pipe, Welded steel pipe, Welded Steel Tube, Hollow pipe, seam welded pipe, Carbon Steel Welded Pipe, Carbon Steel Pipe, cs pipe, mild steel pipe

Materials: S195T, GR.B, X42, X52, X60, CC60, CC70, ST35, ST52, S235JR, S355JR, SGP, STP G370, STPG410, GR2 etc.

Standard: API 5L, ASTM A53, A515, A672, A500, A252, EN10255, EN10217 etc.

SAW is normally operated in the automatic or mechanized mode, however, semi-automatic (hand-held) SAW guns with pressurized or gravity flux feed delivery are available.

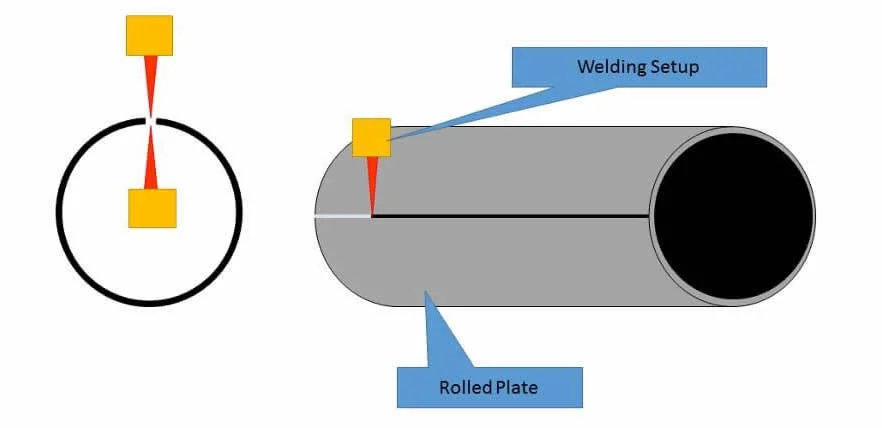

LSAW (Longitudinal double submerge arc welding) carbon steel pipe is a type of SAW pipe made of steel plates that were hot rolled by JCOE or UOE forming technology.

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

Features:

Large diameter steel pipes

Thick walls

High-Pressure resistance

LSAW Welded Steel Pipe Type

SAWL steel pipe, Straight seam steel pipe, Welded steel pipe, Welded Steel Tube, Hollow pipe, seam welded pipe, Carbon Steel Welded Pipe, Carbon Steel Pipe, cs pipe, mild steel pipe

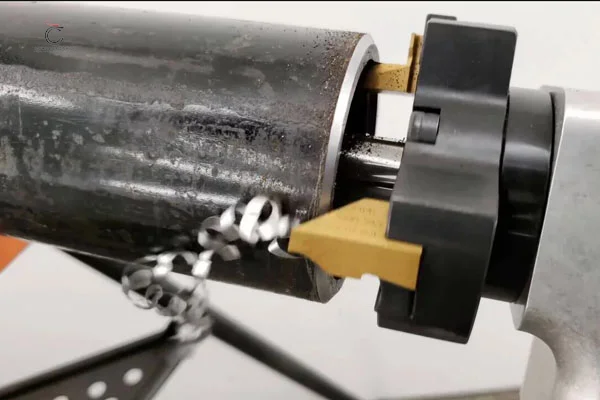

LSAW Welded Steel Pipe Production process

Longitudinal submerged arc welding

SAW Welded Pipe Manufacturing Method

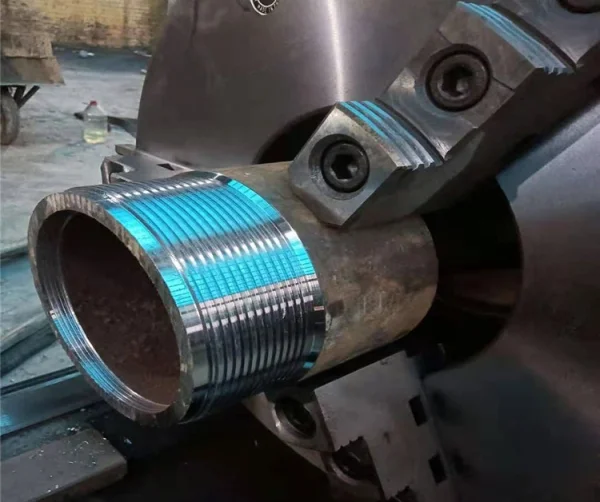

In single seam SAW pipe, wedding is done with the help of submerged arc welding process. In this method, a welding arc is submerged in welding flux. A Continues solid filler wire is fed from the outside. The pipe is welded first inside and then from the outside.

In the case of double seam saw pipe first two halves are joined by tack weld which is called fit-up. Double seam saw pipe is havening a two weld seam opposite to each other. Both the seams are welded from inside and outside of the pipe. In the case of high thickness pipe, multiple pass welding is done.

In a spiral saw pipe, steel plate from the de-coiler is formed in a spiral loop. This spiral loop is then welded from inside and outside of the pipe. Because of the method of manufacture, a wide variety of diameters can be produced. Spiral saw pipes are used for low-pressure services.

Whereas straight saw pipes are used for medium to high-pressure services. Spiral saw pipes are less costly compared to straight saw pipe.

Once the welding is completed heat treatment is carried out on the weld or on the full body of pipe, this depends on the thickness of pipes. Weld seams are also subjected to various non-destructive testing such as RT & UT to ensure the soundness of the weld material.

Once all NDT is completed pipes are hydro tested to ensure strength and ability to remain leak proof under pressure. In the last stage of inspection, the pipe is checked visually and dimensionally by competent inspection engineer. He will ensure that pipe is meeting the code, standard, and specification requirements. Once the Inspection engineer cleared the pipe, it will mark as per the standard requirements & send for the packaging.

LSAW Welded Steel Pipe Specification:

Outer diameter: 16”-56” (406.4mm-1422.4mm).

Wall thickness: 10mm-100mm.Length: 3m-14m

Surface: oiling, spraying black paint ( or varnish), galvanized, 3PE, FBE epoxy anti-corrosion coating etc.

LSAW Welded Steel Pipe Application

Widely used in industry, chemical industry, construction, water treatment, agricultural irrigation, highway billboards, fire fighting , bridge supporting , gas & oil conveying, mine and oilfield drilling.

LSAW Welded Steel Pipe Inspection

We have performed 100% inspection for nine items.

They are the Plate 100% ultrasonic inspection

welded seam 100% continuous ultrasonic inspection after welding

welded seam 100% X-ray industry TV inspection

inside welded seam 100% TV inspection

pipe 100% hydraulic testing

pipe 100% final ultrasonic testing after expansion & hydro testing

100% X-ray industry TV inspection and pipe end inspection image recording

100% pipe visual inspection

100% plate visual inspection.

All the inspections shall be carried out by the specified inspection department.

We can ensure that the quality of the pipes produced by us can meet the requirements of consumers and the standards as well

LSAW Welded Steel Pipe feature

The UOE mill features the most advanced technology and process, achieves high production efficiency, stable product quality and is equipped with complete inspection equipment. UOE mill adopts U & O forming, the formed pipes are welded inside through five internal welding stations with three wires, and welded outside through four external welding stations with three wires. In accordance with different requirements of the customers, the welded pipe can be expanded either by mechanical or hydrostatic expand to improve dimensional accuracy, and eliminate residual stress.

LSAW Welded Steel Pipe is a pipe produced by pressing (rolling) the steel plate into a tube blank in a mold or a forming machine, using a single medium and heavy plate as the raw material, and using double-sided submerged arc welding and expanding the diameter.

LSAW Welded Steel Pipe main characteristic:

1) The steel pipe has a longitudinal weld, and the inner and outer welds are welded by a submerged arc welding.

2) After the overall mechanical expansion treatment, the internal stress of the steel pipe is small and evenly distributed, which can effectively prevent stress corrosion cracking, and has high dimensional accuracy, which is convenient for on-site welding construction.

3) Using the pre-welding and fine welding process, the welding process is stable and the welding seam quality is high.

4) The welding seam is easy to realize the non-destructive inspection in the production process and the non-destructive inspection in the field during the use process.

5) The product specification range is large, which can produce small diameter, large wall thickness and large diameter and large wall thickness steel pipes.

Difference between ERW and SAW steel pipe

As ERW steel pipe and SAW steel pipe in the pipe during forming, welding and process is different, so that two kinds of steel pipe in the performance there are some differences.

ERW steel pipe surface quality is superior to spiral submerged arc welded pipe, ERW steel pipe surface is smooth, smooth, beautiful, SAW steel pipe internal and external weld reinforcement.

ERW steel pipe weld defect types is less than the saw steel pipe. Saw steel pipe with solvent deposited, more types of defects, in addition to volume defects, there are wire-line trap. ERW steel pipe weld defects only wire-line and straight welds, the inspection process easy to follow, and the defects in the maximum reflection at, once the lack of implicit, ultrasonic reflecting the strong, easy to detect.

ERW steel pipe related to saw steel pipe in residual stress ratio is low. Since ERW pipe deformation in the deformation process more fully, coupled subsequent sizing flat oval, elliptical vertical changes and necking, making ERW pipe residual stress becomes smaller. Physical testing showed that the same specifications, the same material ERW pipe after incision along the axis, the axial and transverse incisions smaller displacement than the spiral submerged arc welded pipe.

ERW Pipe overall performance of the same, when the pipe becomes defective, steel scrap judgment, allow welding. SAW steel pipe allowed, and pipe welding performance and overall performance is inconsistent, welding place prone to stress corrosion cracking. Experiments show that stress corrosion fatigue test ERW pipe spiral submerged arc welded pipe length than life.