Product List

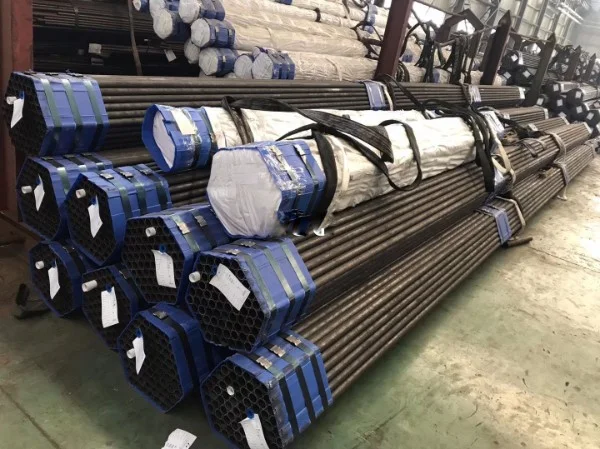

ASTM A53 (ASME SA53) carbon steel pipe is a specification that covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8″ to NPS 26. A53 is intended for pressure and mechanical applications and is also acceptable for ordinary uses in steam, water, gas, and airlines.

A53 pipe comes in three types (F, E, S) and two grades (A, B).

A53 Type S is a seamless pipe found in Grades A and B)

ASTM A53 Grade B Seamless is our most popular product under this specification and A53 pipe is commonly dual-certified to A106 B Seamless pipe.

Chemical Properties %

Description | Grade | c, max | Mn, max | P, max | S, max | Cu*, max | Ni*, max | Cr*, max | Mo*, max | V*, max |

Type S | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

B | 0.30 | 1.20 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

*The total composition for these five elements shall not exceed 1.00%

Mechanical Properties:

Grade A | Grade B | |

Tensile Strength, min., psi, (MPa) | 48,000(330) | 60,000 (415) |

Yield Strength, min., psi, (MPa) | 30,000(205) | 35,000(240) |

Note: This is summarized information from ASME Specification A53. Please refer to the specific Standard or Specification or contact us for more details.)

ASTM A53 seamless steel pipe is an American standard brand.A53-A is equivalent to China's No. 10 material, and A53-B is equivalent to China's No. 20 material.

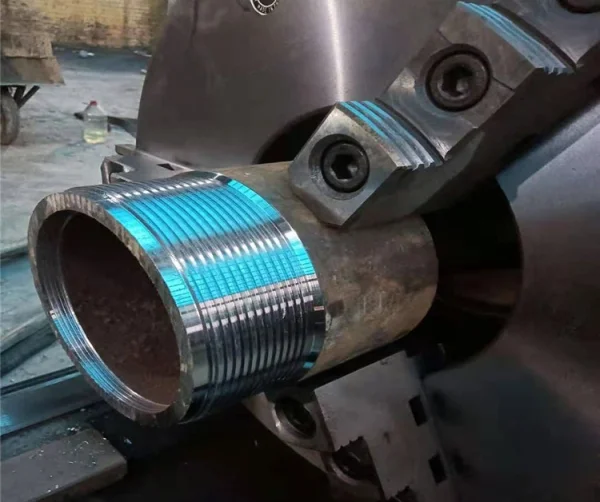

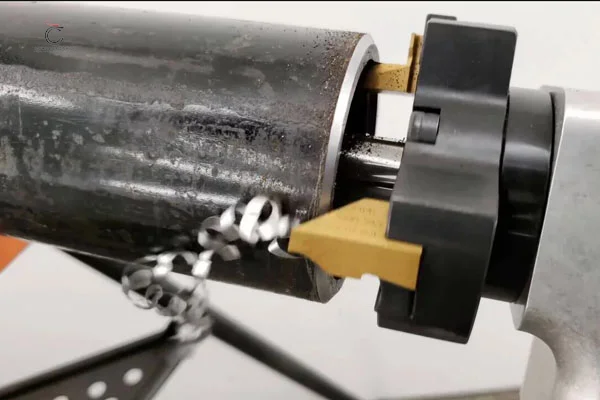

ASTM A53 Seamless stee pipe production process :

The seamless steel pipe manufacturing process is divided into cold seamless pipe &hot-rolled seamless steel pipes.

A: Production process of cold-drawn seamless steel tubes:

Tube blank → heating → perforation → heading → annealing → pickling → oiling → multiple cold drawing → blank tube → heat treatment → straightening → hydraulic test → marking → storage.

B: Production process of hot-rolled seamless steel pipe:

Tube billet → heating → perforation → three-roller/cross-rolling & continuous rolling → de-pipe → sizing → cooling → straightening → hydraulic test → marking → seamless steel pipe with leverage effect detected.